Package Include

Perkins 1204E-E44TA, 1204E-E44TTA, 1206E-E66TA Industrial Engines Troubleshooting Manual

Language

English

File Format

PDF

Total Number of pages

308

Publication Number

KENR9116-01 (May 2011)

Compatible

Windows system / Mac system / Android / IOS

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 4 mb

Overview

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Perkins Engine

Perkins 1204E-E44TA Industrial Engine

Perkins 1204E-E44TTA Industrial Engine

Perkins 1206E-E66TA Industrial Engine

This Troubleshooting Manual very clear and it is 100% printable version , contains with high quality images, Diagrams and instructions

The Factory was highly recommended use this manual for Technicians, before operate or repair your Perkins Engine

Contents of this PDF Service Manual

Troubleshooting Sections

Electronic Troubleshooting

Welding Precaution

System Overview

Glossary

Electronic Service Tools

Indicator Lamps

Replacing the ECM

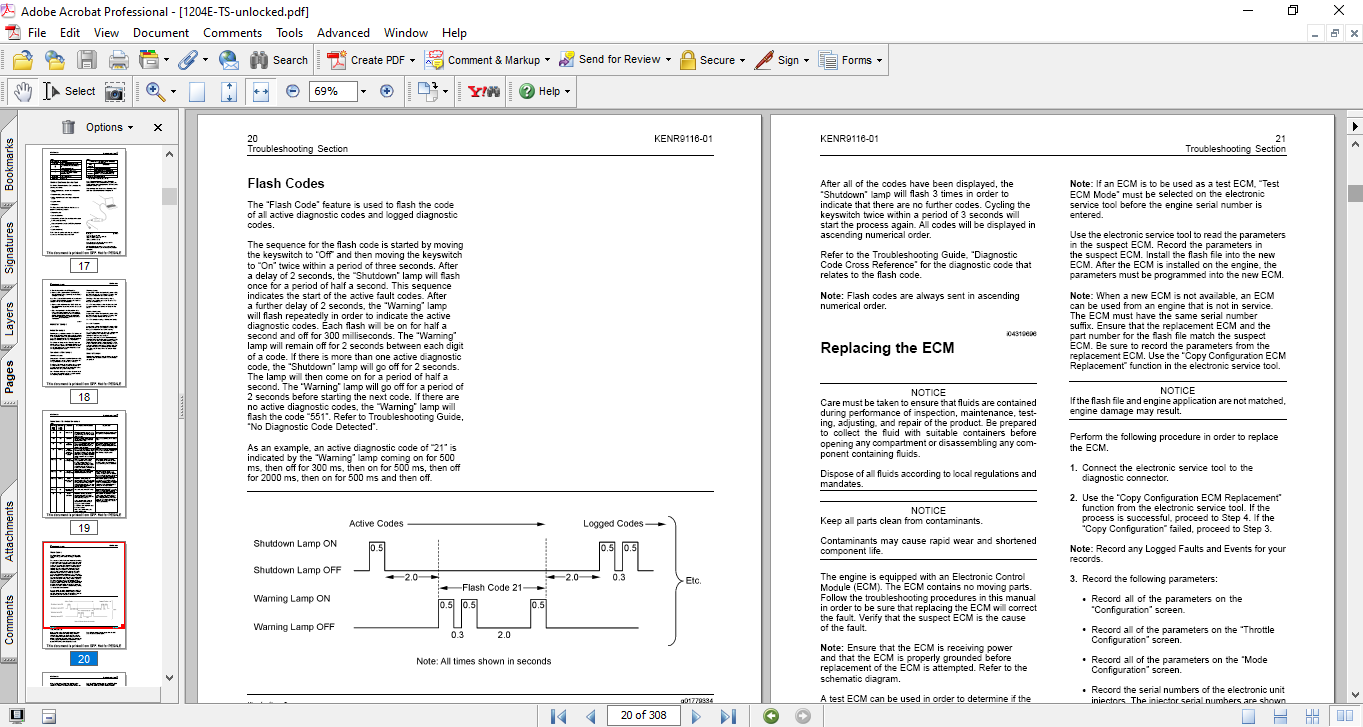

Self-Diagnostics

Sensors and Electrical Connectors

Engine Wiring Information

ECM Harness Connector Terminals

Programming Parameters

Test ECM Mode

Factory Passwords

Flash Programming

Injector Code – Calibrate

Mode Switch Setup

Throttle Setup

Multiposition Switch Setup

Customer Specified Parameters

Customer Specified Parameters Table

Customer Specified Parameters Worksheet

System Configuration Parameters

System Configuration Parameters

Symptom Troubleshooting

Acceleration Is Poor or Throttle Response Is

Poor

Alternator Is Noisy

Alternator Problem

Battery Problem

Coolant Contains Oil

Coolant Level Is Low

Coolant Temperature Is High

Crankcase Breather Ejects Oil

Crankcase Fumes Disposal Tube Has Oil

Draining

Cylinder Is Noisy

Diesel Particulate Filter Collects Excessive Soot

74 Diesel Particulate Filter Temperature Is Low

ECM Does Not Communicate with Other

Modules

ECM Will Not Accept Factory Passwords . ………… 76

Electronic Service Tool Does Not Communicate .. 77 Engine Cranks but Does Not Start

Engine Does Not Crank

Engine Has Early Wear

Engine Has Mechanical Noise (Knock)

Engine Misfires, Runs Rough or Is Unstable

Engine Overspeeds

Engine Shutdown Occurs Intermittently

Engine Speed Does Not Change

Engine Stalls at Low RPM

Engine Top Speed Is Not Obtained

Engine Vibration Is Excessive

Exhaust Has Excessive Black Smoke

Exhaust Has Excessive White Smoke

Fuel Consumption Is Excessive

Fuel Contains Water

Fuel Rail Pressure Problem

Fuel Temperature Is High

Inlet Air Is Restricted

Inlet Air Temperature Is High

Intake Manifold Air Pressure Is High

Intake Manifold Air Pressure Is Low

Intake Manifold Air Temperature Is High

NRS Exhaust Gas Temperature Is High

NRS Mass Flow Rate Problem

Oil Consumption Is Excessive

Oil Contains Coolant

Oil Contains Fuel

Oil Pressure Is Low

Power Is Intermittently Low or Power Cutout Is Intermittent

Valve Lash Is Excessive

Troubleshooting with a Diagnostic Code

Diagnostic Trouble Codes

Diagnostic Code Cross Reference

No Diagnostic Codes Detected

Troubleshooting with an Event Code

Event Codes

Diagnostic Functional Tests

5 Volt Sensor Supply Circuit – Test

Analog Throttle Position Sensor Circuit – Test …. 163 CAN Data Link Circuit – Test

Data Link Circuit – Test

Diesel Particulate Filter Identification Signal -Test

Digital Throttle Position Sensor Circuit – Test

ECM Memory – Test

Electrical Connectors – Inspect

Engine Pressure Sensor Open or Short Circuit -Test

Engine Speed/Timing Sensor Circuit – Test

Engine Temperature Sensor Open or Short Circuit -Test

Engine Temperature Sensor Open or Short Circuit -Test

Ether Starting Aid – Test

Fuel Pump Relay Circuit – Test

Glow Plug Starting Aid – Test

Idle Validation Switch Circuit – Test

Ignition Keyswitch Circuit and Battery Supply Circuit –

Test

Indicator Lamp Circuit – Test

Injector Data Incorrect – Test

Injector Solenoid Circuit – Test

Mode Selection Circuit – Test

Motorized Valve – Test

PTO Switch Circuit – Test

Sensor Calibration Required – Test

Solenoid Valve – Test

Soot Sensor – Test

Throttle Switch Circuit – Test

Valve Position Sensor – Test

Water In Fuel Sensor – Test

About us and our vision

OUR VISION : 100 % CUSTOMER SATISFACTION, AFTER SALE SERVICE AND KEEP IN TOUCH WITH OUR REGULAR CLIENTS

Until download and place it on your computer We care with you ,We really try our best to complete your orders, so your review is very important to us to improve our services

www.repair-manuals.com | What we offer to our customers

Here with we provide Original factory Service Manuals , Repair Manuals , Workshop Manuals , Parts Manuals, Technical Manuals , Operator’s Manuals, Owner Manuals, Electrical Diagrams , Hydraulic Diagrams and many more manuals for heavy mechanic industry

Thank you for choosing www.repair-manuals.com, We appreciate your business!