| Package include | Tigercat L855D Feller Buncher Service Repair Manual |

| Language | English |

| File Format | |

| Total Number of pages | 742 |

| Publication Number | 47655AENG / ISSUE 2.0, MAY 2021 |

| Compatible | Windows system / Mac system / Android / IOS / Chrome OS / Any device capable of opening a PDF file |

| Additional Requirement | User must have any software that can open the pdf format |

| Shipping Policy | All of our products are digital and hence supplied immediately upon purchase. Once your purchase is complete, you will have immediate access to the product via a download link |

| Download Size | Total download size: 118 MB |

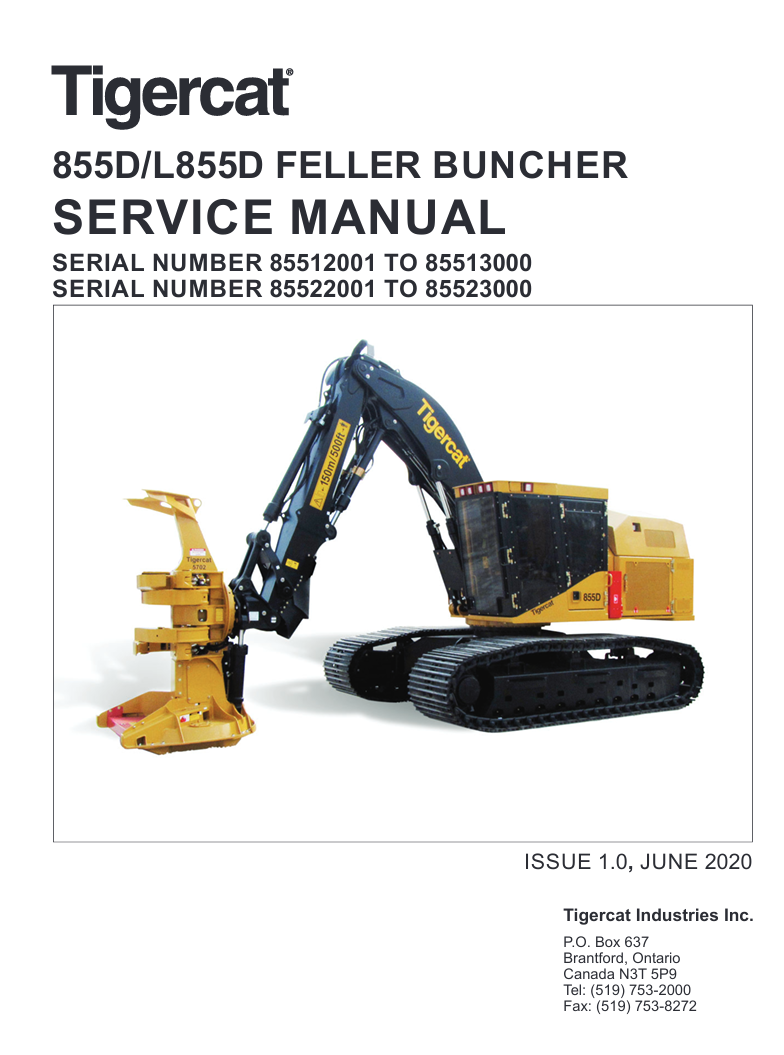

| Compatible Machine Models | Tigercat L855D Feller Buncher |

| Compatible Serial Number Range | SERIAL NUMBER 85512001 TO 85513000 |

| SERIAL NUMBER 85522001 TO 85523000 | |

| Sample Preview Yes | Before purchasing the entire pdf handbook, please get sample preview of this pdf manual and ensure it is suitable with your model |

| Sample Preview Link | DOWNLOAD SAMPLE PREVIEW |

Understanding the Tigercat L855D Feller Buncher

The Tigercat L855D Feller Buncher is a highly efficient logging machine designed for the various demands of timber harvesting. Engineered with robust specifications and advanced technology, this feller buncher stands out in environments requiring precision and power. The L855D boasts a powerful engine that delivers exceptional performance while ensuring optimal fuel efficiency, making it an environmentally conscious choice for logging operations. The engine is complemented by an efficient hydraulic system that provides precise control over the machine’s multiple functions, enhancing its overall functionality.

One of the key features of the Tigercat L855D is its specialized boom and cutting attachment, which allows for effective felling and bunching of trees. This enables operators to maximize productivity by cutting and organizing timber in a single motion, significantly improving operational efficiency. The machine’s design includes a low center of gravity, which contributes to improved stability and maneuverability on uneven terrain. These characteristics make the L855D suitable for various logging environments, from steep hillsides to flatlands, accommodating diverse operational needs.

The hydraulic system is particularly noteworthy, utilizing advanced technology to manage power distribution and enhance response times. This system enables the feller buncher to handle varying workloads seamlessly, making it a reliable asset in both small-scale and large-scale logging operations. Additionally, the L855D’s ergonomic design aids operator comfort, reducing fatigue during extended periods of operation.

The Tigercat L855D is well-regarded for its robust performance and reliability, offering notable advantages over other models in its class. Its combination of engineering excellence, efficiency, and operator-friendly features positions it as a preferred choice for logging professionals. Understanding these aspects of the L855D is crucial for those considering its implementation in forestry projects.

Service and Repair Manual: Best Practices and Maintenance Tips

The Tigercat L855D Feller Buncher is a complex piece of machinery that requires diligent care and maintenance to ensure it operates at peak efficiency. Utilizing the service and repair manual is fundamental for operators and technicians alike, as it provides essential guidance on how to maintain the equipment properly. This manual is designed to cover a wide range of topics, including routine inspections, preventative maintenance, and troubleshooting common issues that may arise during operation.

One of the primary recommendations outlined in the service manual is the importance of conducting regular inspections. Operators should establish a structured schedule to inspect critical components such as hydraulic systems, engine performance, and the undercarriage. Regular checks not only help identify potential problems early but also contribute to the overall longevity of the feller buncher. Additionally, cleaning the machine after each job can prevent the buildup of debris and contaminants, which can adversely affect performance.

Moreover, the manual emphasizes the significance of addressing minor issues promptly before they escalate into major repairs. The troubleshooting section provides step-by-step guidance for diagnosing common problems that may occur. By adhering closely to the outlined procedures, operators can significantly enhance their ability to perform effective repairs and maintenance, maximizing equipment uptime.

It is crucial to utilize only genuine Tigercat parts when performing repairs. The service manual outlines the specifications for these components to ensure compatibility and reliability. Using OEM (original equipment manufacturer) parts guarantees that the machine will continue to function optimally and comply with safety protocols. This practice not only protects the machine’s integrity but also maintains the warranty provided by the manufacturer. By following the best practices and guidelines outlined in the Tigercat L855D Feller Buncher service manual, operators can ensure their equipment remains reliable and efficient over its lifespan.