Package Include

Komatsu HM300-2 Japan Dump Truck S.N 2001-UP Workshop Manual

Language

English

Format

PDF

Total Number of pages

1367

Publication Number

SEN00237-14

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 67 mb

With This Original factory Workshop Manual The Technician can solve any problems encountered in the operation of your Komatsu Dump Truck Models of :

HM300-2 Japan Dump Truck [ S.N 2001-UP ]

[True Electronic pdf copy with contains high quality images and diagrams, not scanned version]

The Komatsu HM300-2 Japan Dump Truck Workshop Manual is an essential resource for maintenance and repair professionals, providing comprehensive guidance on the operation and servicing of this robust vehicle. This manual includes detailed diagrams, troubleshooting tips, and step-by-step instructions, ensuring that you can efficiently address any issues that may arise. With its user-friendly format and in-depth technical information, this workshop manual is designed to enhance your understanding and keep your dump truck running smoothly, ultimately saving you time and money on repairs

Table of contents

00 Index and foreword

Index SEN00324-14

Composition of shop manual

Table of contents

Foreword and general information SEN00325-04

Safety notice

How to read the shop manual

Explanation of terms for maintenance standard

Handling of electric equipment and hydraulic component

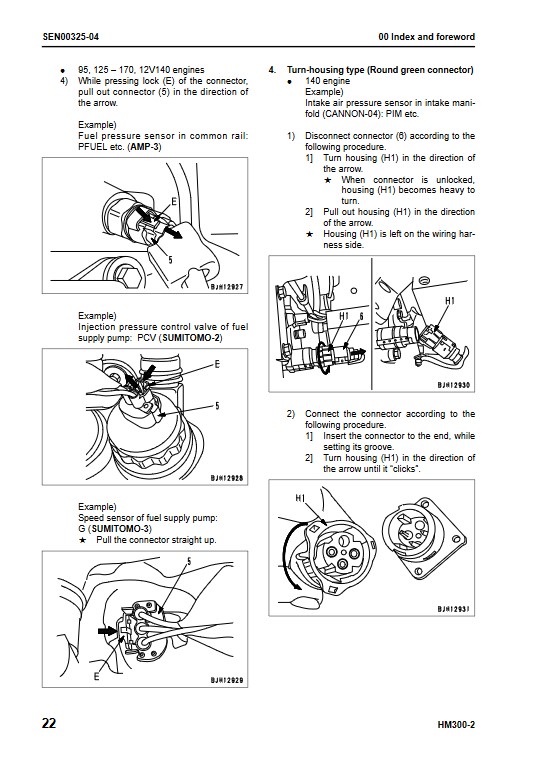

Handling of connectors newly used for engines

How to read electric wire code

Precautions when carrying out operation

Method of disassembling and connecting push-pull type coupler

Standard tightening torque table

Conversion table

01 Specification

Specification and technical data SEN00327-01

Specification drawings

Specifications

Weight table

Fuel, coolant and lubricants

10 Structure, function and maintenance standard

Engine and cooling system SEN00329-01

Radiator, oil cooler, aftercooler

Output shaft

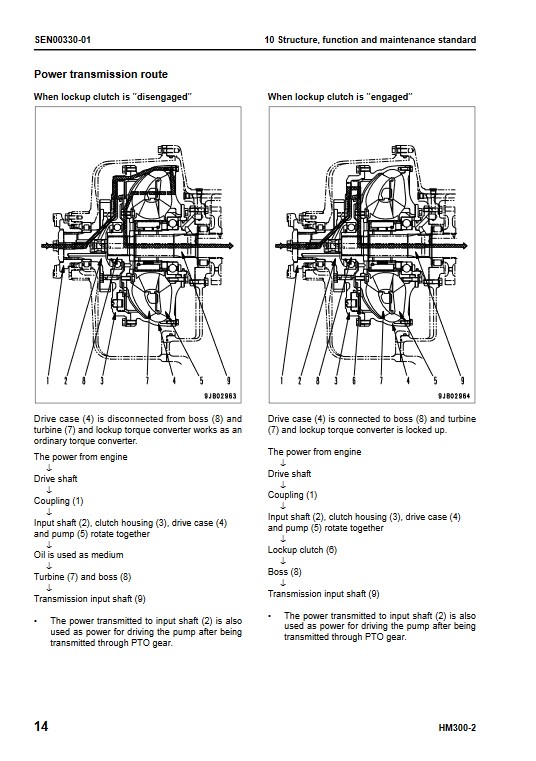

Power train, Part 1 SEN00330-01

Power train skeleton

Torque converter and transmission hydraulic piping

Brake cooling oil control valve (BCV)

Power train pump

Torque converter

Transmission

Transmission control valve

ECMV

Main relief, torque converter relief valve

Power train, Part 2 SEN00417-01

Drive shaft

Axle

Differential

Limited slip differential

Final drive

Steering system SEN00331-01

Steering column

Brake system SEN00332-02

Brake piping

Brake valve

Accumulator charge valve

Accumulator

Slack adjuster

Brake

Proportional reducing valve

Brake system tank

Parking brake

Parking brake solenoid

Undercarriage and frame SEN00333-01

Suspension

Suspension cylinder

Oscillation hitch

Hydraulic system SEN00334-02

Steering, hoist oil pressure piping diagram

Dump body control

Hydraulic tank and filter

Flow amp valve

Steering valve

Steering cylinder

Hoist valve

Dump control valve (EPC valve)

Hoist cylinder

Hydraulic pump

Cab and its attachments SEN00335-01

ROPS cab

Cab tilt

Air conditioner

Rear view monitor

Controller related

Electrical system, Part 1 SEN00336-01

Machine monitor system

Electrical system, Part 2 SEN00418-02

Automatic shift control system

Retarder control system

Auto emergency steering system

Battery disconnector switch

Dump control lever

Electrical system, Part 3 SEN04841-00

Payload meter (Card type)

Electrical system, Part 4 SEN00419-02

Sensors, switches

KOMTRAX terminal system (If equipped)

20 Standard value table

Standard service value table SEN00416-03

Standard value table for engine

Standard value table for chassis

30 Testing and adjusting

Testing and adjusting, Part 1 SEN00667-05

Tools for testing, adjusting, and troubleshooting

Sketches of special tools

Testing engine speed

Testing intake air pressure (boost pressure)

Testing exhaust temperature

Testing exhaust gas color

Adjusting valve clearance

Testing compression pressure

Testing blow-by pressure

Testing engine oil pressure

Testing EGR valve and bypass valve drive oil pressure

Handling of fuel system devices

Releasing residual pressure from fuel system

Testing fuel pressure

Handling during cylinder cut-out operation

Handling during no injection cranking operation

Testing fuel return and leak amount

Bleeding air from fuel circuit

Testing fuel circuit for leakage

Testing and adjusting alternator belt tension

Testing and adjusting air conditioner compressor belt tension

Adjusting the shims in the body mount

Testing and adjusting, Part 2 SEN00668-06

Testing torque converter stall speed

Testing power train oil pressure

Adjusting transmission speed sensor

Testing and adjusting brake oil pressure

Testing of accumulator nitrogen gas pressure and procedure for charging accumulator with nitrogen

gas

Testing brake performance

Bleeding air from brake circuit

Testing wear of wheel brake disc

Testing wear of parking brake pad

Method for emergency release of parking brake

Testing and adjusting steering circuit oil pressure

Testing and adjusting suspension cylinder

Method of tilting cab up

Testing and adjusting dump circuit oil pressure

Adjusting body positioner sensor

Procedure for adjusting length of spring in body heating spherical joint

Handling engine controller high voltage circuit

Adjusting transmission controller

Method for emergency escape at electrical system failure

Testing and adjusting, Part 3 SEN00669-03

Setting and adjusting various equipments

Special function of machine monitor (EMMS)

How to start operation of KOMTRAX terminal

Lamp display of KOMTRAX terminal

Pm Clinic check sheet

40 Troubleshooting

Failure code table and fuse locations SEN03299-01

Failure codes table

Fuse locations

General information on troubleshooting SEN00670-04

Points to remember when troubleshooting

Sequence of events in troubleshooting

Checks before troubleshooting

Classification and procedures for troubleshooting

Information in troubleshooting table

Connection table for connector pin numbers

T-branch box and T-branch adapter table

Troubleshooting by failure code, Part 1 SEN00671-03

Troubleshooting by failure code, Part 2

Troubleshooting by failure code, Part 3

Disassembly and assembly of operator’s seat assembly

Diagrams and drawings

Electrical diagrams and drawings