Product Code DSN 0036 [ After payment, this Code helps to receive correct download password to your Account Dashboard ]

Package Include

Doosan Diesel Engine 5.8Liter DB58S Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-152

Publication Number

SB4118E01 May.2007

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 23 mb

Overview

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Doosan Engine Models of :

Diesel Engine 5.8Liter (DB58S)

Related with :

D35S-5, D40S-5, D45S-5, D50C-5, D55C-5

D50S-5, D60S-5, D70S-5, D80S-5, D90S-5 (3 speed)

D50S-5, D60S-5, D70S-5 (2 speed)

The Factory was highly recommended use this manual for Technicians before you touch your Doosan Engine

This is Original factory pdf manual and This pdf Workshop Manual very clear and it is 100% printable version, contains with high quality images and circuit diagrams

DOWNLOAD SAMPLE OF THIS PDF MANUAL

Table of Contents of Workshop Manual

GENERAL INFORMATION

Engine specifications

Performance curve

Performance curve (ECRFA), D50/60/70/80/90S-5 (3 speed)

Performance curve (ECRFD), D35/40/45S-5, D50/55C-5

Performance curve (ECRFE), D50/60/70S-5 (2 speed)

Engine assembly

Engine assembly view (ECRFA), D50/60/70/80/90S-5 (3 speed)

Engine assembly view (ECRFD), D35/40/45S-5, D50/55C-5

Engine assembly views (ECRFE), D50/60/70S-5 (2 speed)

Safety regulations

General notes

Regulations designed to prevent accidents

Regulations designed to prevent damage to engine and premature wear

Regulations designed to prevent pollution

General repair instructions

TECHNICAL INFORMATION

Engine model and serial number

Engine type

Cylinder block

Piston con-rod / crankshaft

Engine timing

Valves

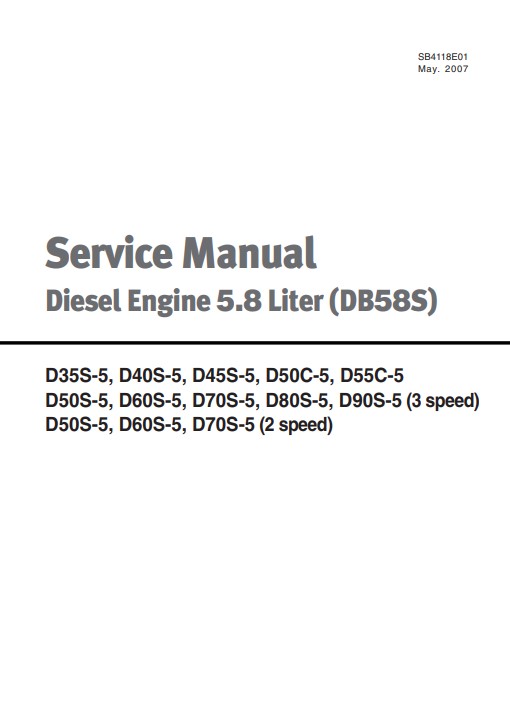

Lubrication system

Recommend of lubricating oil

Oil cooler

Oil filter

Air cleaner

Fuel system

Injection pump

Fuel filter

Fuel requirements

How to select fuel oil

Cooling system

Anti-freeze

Cooling water

V-belt tension check and adjust

Valve clearance and adjustment

Cylinder compression pressure

Injection nozzle

Battery

Starting motor

Diagnosis and remedy

Engine inspection

Stopping engine

General engine inspection cycle36

Use of original parts for repair and replacement

MAINTENANCE

3.1. Engine Disassembly

Major part fixing nuts and bolts

Main structure parts (1)

Main structure parts (2)

Rocker arm disassembly

Cylinder head disassembly

Piston and connecting rod disassembly

Engine Inspection

Cylinder block

Cylinder head

Valve stem and valve guide clearance

Valve spring

Tappet

Push rod

Rocker arm correction

Idler gear and shaft

Camshaft

Cylinder liner

Cylinder block

Piston

Maintenance of cylinder block, cylinder liner and piston

Connecting rod

Crankshaft

Flywheel and flywheel housing

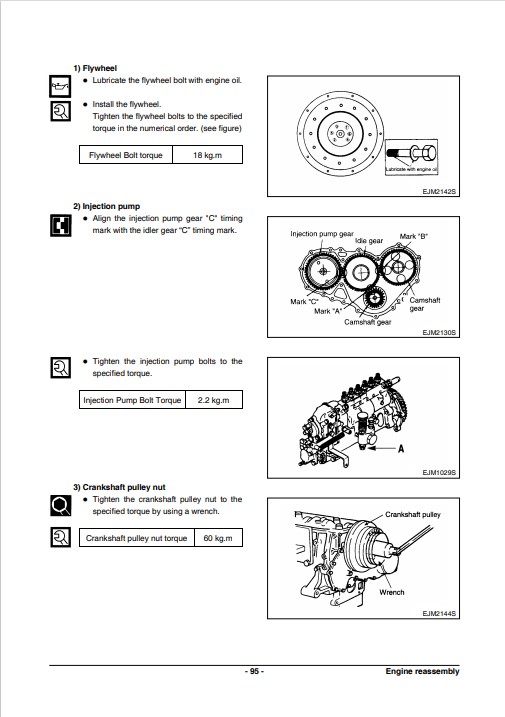

Engine Reassembly

Piston and connecting rod assembly

Cylinder head assembly parts

Rocker arm and shaft assembly

Main components

Major component assembly

External parts

COMMISSIONING AND OPERATION

Preparation

Starting

Starting and operation

Operation of a new engine (Break-In)

Check points for break-in

Inspections after starting

Operation in winter time

Prevention against the freeze of cooling water

Prevention against excessive cooling

Lubricating oil

Starting of engine in winter

Tuning the engine

Maintenance and care

Periodical inspection and maintenance

Exchanging of lubrication oil

Oil level

Oil exchange procedure

Replacement of oil filter cartridge

Cooling system

Coolant draining

Cleaning of the cooling inside system circuit

Valve clearance and adjustment

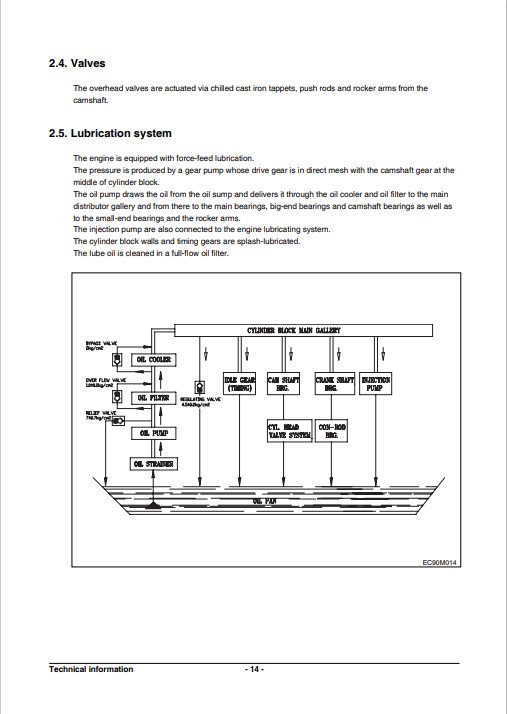

Injection timing

Tightening the cylinder head bolts

Fuel injection pump

Feed pump strainer

Separator (Add if necessary)

Air bleeding

Belts

Maintenance of Major Components

Lubrication system

Oil pump

Oil cooler

Cooling system

Water pump

Thermostat

Fuel system

Fuel filter

Injection nozzle

Injection Pump Calibration

Precautions for operation

Walk-around check and servicing

Diagnostics and troubleshooting

Special Tool List