Package Include

Bomag BC672 RB-2, BC772 RB-2, BC772 RS-2, BC672 EB-2, BC772 EB-2 Compactor Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1022

Publication Number

008 911 53 (10/2010)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 57 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bomag Compactor Models of :

Sanitary landfill compactor Fast moving soil compactor

BC 672 RB-2 / BC 772 RB-2 / BC 772 RS-2 / BC 672 EB-2 / BC 772 EB-2

S/N 101 570 59 …. S/N 101 570 58 …. S/N 101 570 57 ….

S/N 101 570 93 …. S/N 101 570 92 …..

This Service Manual very clear, This is True Electronic pdf copy, not scanned version, contains high quality images and it is 100% printable version

Ensure the longevity and optimal performance of your Bomag compactor with the comprehensive Service Repair Manual for models BC672 RB-2, BC772 RB-2, BC772 RS-2, BC672 EB-2, and BC772 EB-2. This manual provides detailed instructions, troubleshooting tips, and maintenance guidelines, empowering you to tackle repairs with confidence. With clear diagrams and step-by-step procedures, you can minimize downtime and keep your equipment running smoothly, making it an essential resource for any operator or technician. Invest in your machinery’s reliability and efficiency today

Contents of this pdf manual

General

Introduction

Safety regulations

General repair instructions

Tightening torques

Technical data

Maintenance

General notes on maintenance

Fuels and lubricants

Table of fuels and lubricants

Running-in instructions

Maintenance table

Electrics

Understanding circuit diagrams

Designation of components in the wiring diagram

Terminal designations in wiring diagram

Circuit symbols in the circuit diagram

Battery ground and analog ground

Current and voltage

Resistance

Series / parallel connection

Ohm’s law

Electrical energy

Formula diagram

Metrology

Diodes, relays, fuses

Telemecanique switch

Plug connectors

Magnetic coil plug

Deutsch plug, series DT and DTM

Plugs and terminals in spring clamping technology

Batteries

Battery service, check the main battery switch

Starting the engine with jump leads

Main battery switch

Main fuse

Hydraulic oil temperature

Pressure switch, hydraulic oil filter

Magnetic sensor, hydraulic oil

Pressure switch for brake

Level sensor in diesel tank (R03)

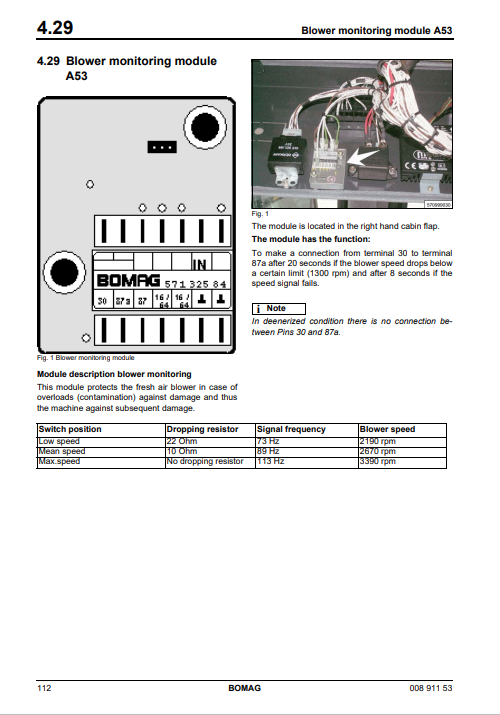

Blower monitoring module A53

Cab electrics

Fuses

Fuse, cabin

Machine related electrics

Electronic control units

Checking the voltage supply for the control unit

Diagnostics concept

Engine electrics

Engine control unit

Pin assignment

System faults indicated by flashing code

Flashing code

Diagnose with SERDIA

Diagnose with CAN-bus

Diagnostics interface

EMR3 List of fault codes

Sensors

Oil pressure sensor

Fuel temperature sensor

Charge air temperature – charge air pressure sensor

EMR coolant temperature sensor

Rotary speed sensor for crankshaft

Rotary speed sensor for camshaft

Preheating system

Checking the preheating system. Maintenance in case of frost.

Sensor, water in fuel

Air filter vacuum switch

Coolant temperature sensor

Float switch, coolant tank

Charge control light, engine RPM-meter

Generator

Replacing the voltage regulator

Electric starter

Electronic control

ESX control

Trouble shooting

Notes on trouble shooting

The machine drives with the travel lever in „NEUTRAL“

The machine does not drive 347

Machine travels to one direction only or to one travel direction with reduced power

Hydraulic oil overheating

Insufficient travel power, max speed is not reached

No steering function / steering stiff, end stops are not reached

Failure of central lubrication system (grease emerges from relief valve)

Trouble shooting travel system

Trouble shooting working hydraulics

Installed components / connection overview

List of installed components

Measuring and adjustment points on tandem travel pump unit

Connection overview

Measuring and adjustment points on control valve block

Air conditioning system

Physical basics

Refrigerant R134a

Compressor oil / refrigeration oil

Working principle of the air conditioning system

Monitoring devices

Description of components

Climatronic control

Measuring the compressor oil level

Checking the magnetic clutch

Inspection and maintenance work

Servicing the air conditioning

Check condition and tension of refrigerant compressor V-belt, replace the V-belt

Drying and evacuation

Emptying in case of repair

Leak test

Filling instructions

Trouble shooting in refrigerant circuit, basic principles

Trouble shooting, refrigerant circuit diagram

Trouble shooting procedure

Steam table for R134a

Central lubrication system

System layout

Technical description

Control

Lubrication process

Progressive distributor

Lubrication oil pump

Check the central lubrication system, topping up

Faults and causes

Fault – Cause – Remedy

Failure of central lubrication system (grease emerges from relief valve)

Engine

Diesel engine

Engine description TCD 2015 V 6 cylinder

Lubrication oil circuit TCD 2015

Coolant circuit TCD 2015

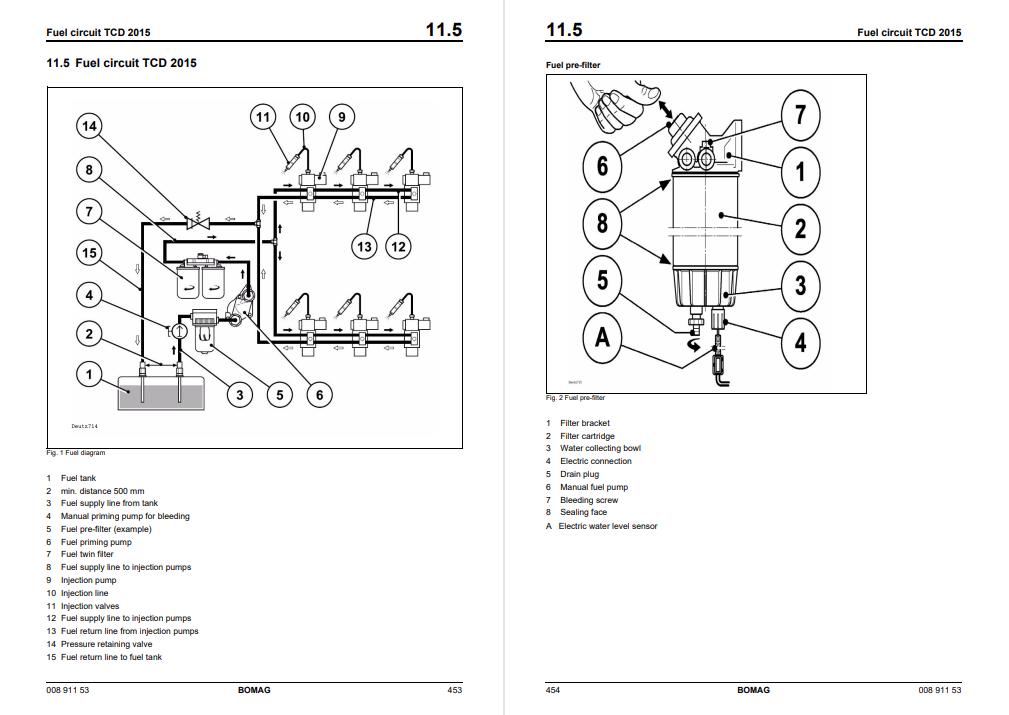

Fuel circuit TCD 2015

Injection system (MVS) TCD 2015

Exhaust gas recirculation TCD 2015

Wastegate – charge pressure controller on TCD-engines

Check, adjust the valve clearance

Check the engine oil level

Change the engine oil

Changing the engine oil filter

Replacing the fuel pre-filter cartridge, bleeding the fuel system

Changing the fuel filter cartridge

Checking condition of radiator, intercooler and hydraulic oil cooler, clean,

cleaning the engine

Changing the coolant, venting the cooling system

Checking the anti-freeze concentration

Checking the thermostat in disassembled state

Servicing the fan V-belt

Checking the condition and tension of the generator V-belt, replacing the V-belt

Check the engine mounts

Checking the fastening of engine / turbo charger / combustion air hoses

General trouble shooting chart TCD 2015

Special tools, Deutz engine (TCD 2015)

Working hydraulics

Hydraulic system

Working hydraulics

Steering and working pump

Control valve block, steering and dozer blade

Tests and adjustments in working hydraulics

Measuring and adjustment points on control valve block

Tests and adjustments on the steering/working pump

Travel hydraulics

Hydraulic system

Travel system (general description)

Travel pump

Travel motors

Filtration

Transfer box filter unit

Tests and adjustments in travel hydraulics

Measuring and adjustment points on tandem travel pump unit

Pressure tests in the travel circuit 544

Checking high pressure relief valves and pressure override

Charge pump high pressure test

Travel pump high pressure test (individual test)

Checking charge pressure

Adjusting the DA-control valve

Checking the control chamber pressure

Measuring and adjustment points on travel motors

Checking the displacement setting of the travel motors

Filter unit for transfer box / pressure relief valve

Special tools, tests and adjustments

Oscillating articulated joint

Removing and installing live ring, oscillating articulated joint

Repairing the oscillating articulated joint

Removing and installing the steering cylinders

Suppliers documentation

Travel pump

Steering/working pump

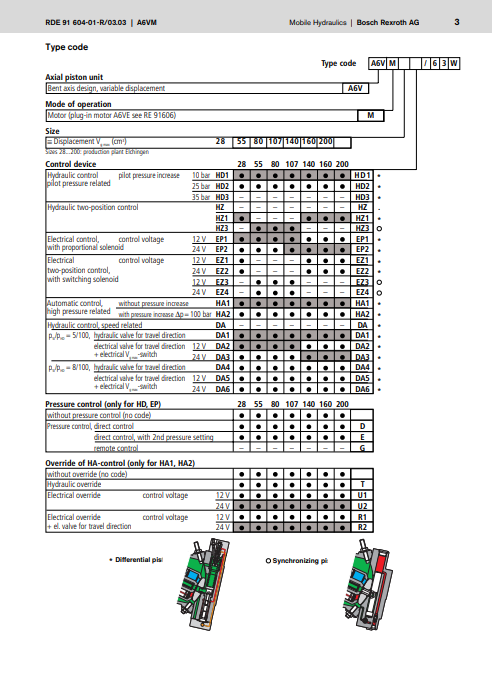

Travel motor

Wheel drive

Control valve block

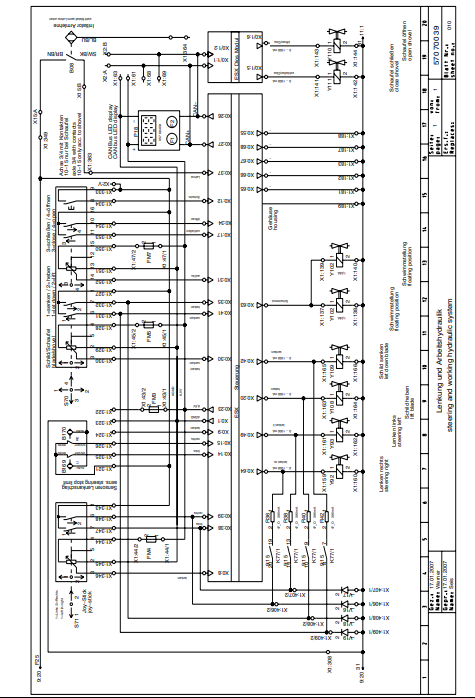

Circuit diagrams

Hydraulic diagram

Wiring diagram