| Package include | Tigercat LH855D Harvester Service Repair Manual |

| Language | English |

| File Format | |

| Total Number of pages | 682 |

| Publication Number | 44985AENG / ISSUE2.0,FEBRUARY2020 |

| Compatible | Windows system / Mac system / Android / IOS / Chrome OS / Any device capable of opening a PDF file |

| Additional Requirement | User must have any software that can open the pdf format |

| Shipping Policy | All of our products are digital and hence supplied immediately upon purchase. Once your purchase is complete, you will have immediate access to the product via a download link |

| Download Size | Total download size: 118 MB |

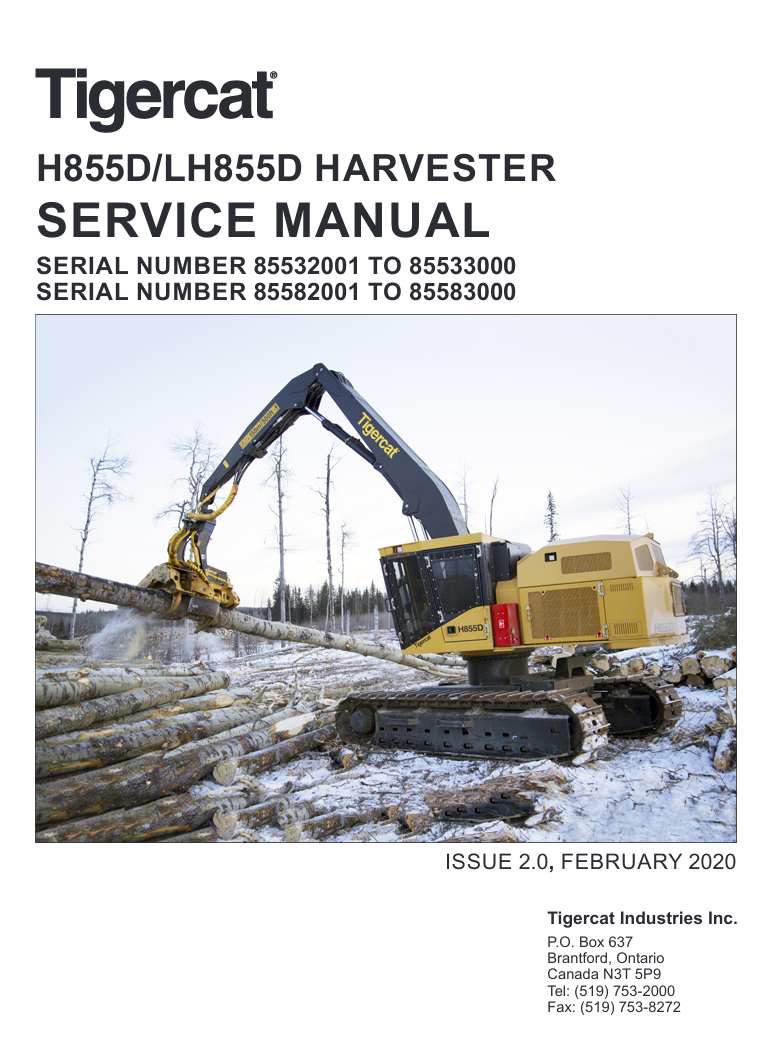

| Compatible Machine Models | Tigercat LH855D Harvester |

| Compatible Serial Number Range | SERIAL NUMBER 85532001 TO 85533000 |

| SERIAL NUMBER 85582001 TO 85583000 | |

| Sample Preview Yes | Before purchasing the entire pdf handbook, please get sample preview of this pdf manual and ensure it is suitable with your model |

| Sample Preview Link | DOWNLOAD SAMPLE PREVIEW |

Overview of the Tigercat LH855D Harvester

The Tigercat LH855D harvester is a state-of-the-art machine designed to excel in various forestry operations, thanks to its robust construction and advanced engineering. This harvester stands out in the forestry sector for its exceptional performance and reliability, making it a preferred choice for professionals engaging in timber harvesting. The LH855D features a powerful diesel engine, capable of delivering impressive horsepower, ensuring efficient operation even in demanding terrains.

This harvester’s specifications reveal a commitment to durability and user-friendly design. The LH855D is equipped with a purpose-built undercarriage that enhances stability and traction, allowing it to navigate through challenging environments. Additionally, its advanced hydraulic system optimizes performance for cutting and processing timber, contributing to improved productivity on the job. The machine’s robust frame and heavy-duty components are tailored to withstand the rigors of forestry applications, thereby reducing downtime and maintenance costs.

The cutting capabilities of the Tigercat LH855D are noteworthy, featuring a variety of cutting heads adaptable to different tree species and sizes, facilitating versatility in operations. The operator control systems are designed for ease of use, ensuring that operators can perform tasks efficiently and with precision. This enhances not only productivity but also overall safety, as operators can maintain better control of the machine in complex environments.

Another key aspect of the LH855D harvester is its design philosophy, which prioritizes both performance and environmental sustainability. The machine’s fuel-efficient engine reduces emissions, aligning with industry trends focused on minimal environmental impact. Overall, the Tigercat LH855D harvester embodies a seamless blend of technological innovation, durability, and operational efficiency, making it an indispensable tool in modern forestry operations.

Importance of a Service Repair Manual

The significance of having a service repair manual for the Tigercat LH855D harvester cannot be understated. This manual serves as a comprehensive resource that provides critical information necessary for maintaining, troubleshooting, and repairing the machine effectively. With a well-structured service repair manual, operators and technicians can enhance the performance and lifespan of the harvester significantly.

One of the primary benefits of the service manual lies in its detailed diagrams and parts lists, which facilitate a clearer understanding of the machine’s components. These visual aids help in quickly identifying parts that require attention or replacement. Additionally, the manual includes step-by-step repair instructions, allowing users to perform repairs with accuracy and efficiency. This structured guidance not only simplifies complex procedures but also boosts the confidence of individuals undertaking maintenance work.

Furthermore, the diagnostic procedures outlined in the service manual are invaluable. Troubleshooting becomes more systematic when users have access to a comprehensive guide that showcases potential issues and their corresponding solutions. This approach minimizes downtime, as operators can quickly identify and address problems as they arise, ensuring the harvester remains operational.

Cost-saving benefits also accompany the utilization of a service repair manual. By following the guidelines provided within the manual, operators can undertake a significant portion of the maintenance work themselves. This reduces reliance on professional services, which can be costly. Engaging in DIY repairs, as recommended by the manual, also fosters a deeper understanding of the machine, promoting proactive maintenance practices.

Safety precautions mentioned in the service repair manual are equally important. The manual provides guidance on the proper techniques to observe while servicing the harvester, ensuring the safety of the operator. By adhering to these precautions, users can prevent accidents and maintain a secure workplace.