| Package include | Tigercat LH855E Harvester Service Repair Manual |

| Language | English |

| File Format | |

| Total Number of pages | 816 |

| Publication Number | 51125AENG / ISSUE 2.0, APRIL 2020 |

| Compatible | Windows system / Mac system / Android / IOS / Chrome OS / Any device capable of opening a PDF file |

| Additional Requirement | User must have any software that can open the pdf format |

| Shipping Policy | All of our products are digital and hence supplied immediately upon purchase. Once your purchase is complete, you will have immediate access to the product via a download link |

| Download Size | Total download size: 127 MB |

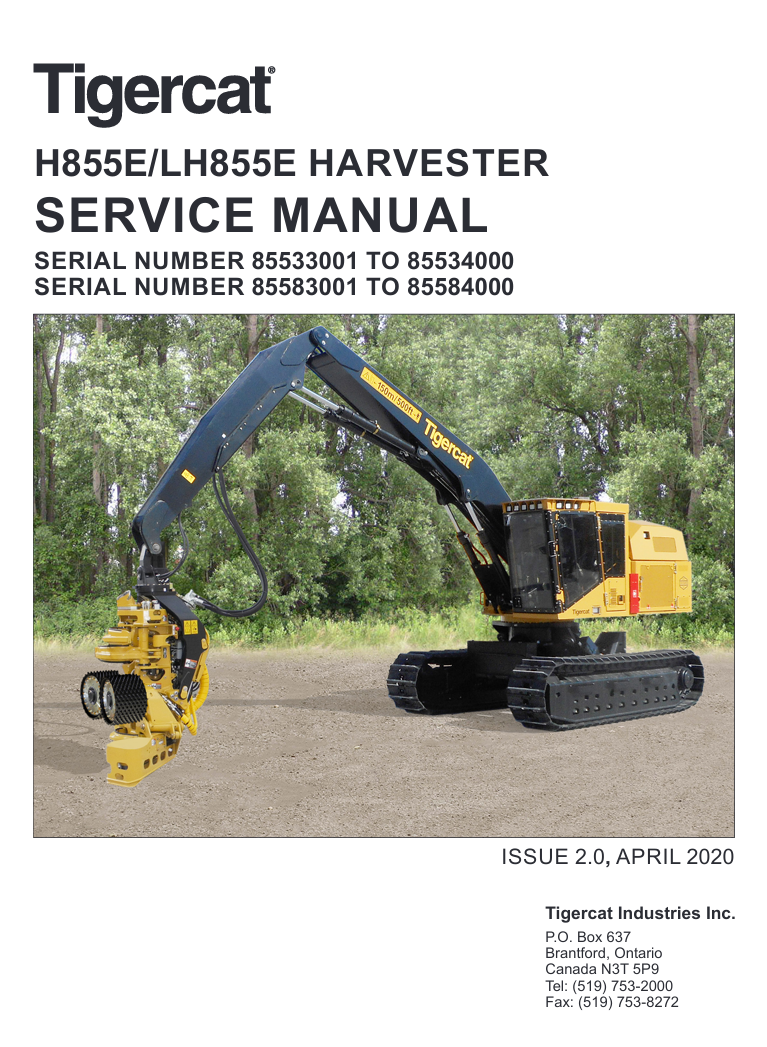

| Compatible Machine Models | Tigercat LH855E Harvester |

| Compatible Serial Number Range | SERIAL NUMBER 85533001 TO 85534000 |

| SERIAL NUMBER 85583001 TO 85584000 | |

| Sample Preview Yes | Before purchasing the entire pdf handbook, please get sample preview of this pdf manual and ensure it is suitable with your model |

| Sample Preview Link | DOWNLOAD SAMPLE PREVIEW |

Understanding the Tigercat LH855E Harvester

The Tigercat LH855E Harvester is a versatile and robust machine designed for optimal performance in the forestry industry. This harvester is equipped with a powerful engine, offering impressive specifications that enhance its efficiency in various operational environments. The LH855E boasts a rated engine output of 197 kW (265 hp), providing the necessary power to handle a range of tasks, from felling to processing timber. It features advanced hydraulic systems that contribute to its superior maneuverability and precision during operations.

One of the distinguishing capabilities of the Tigercat LH855E is its ability to work seamlessly in challenging terrains. The harvester’s design incorporates an advanced mobility system, ensuring stability and traction even in wet or uneven conditions. Its unique all-terrain configuration, combined with an integrated leveling system, allows for enhanced performance in rugged landscapes, making it particularly suitable for diverse logging operations. Moreover, the machine’s compact design helps to navigate tighter spaces, enabling operators to maximize productivity without compromising on efficiency.

Despite its robust design, like any machinery, the Tigercat LH855E can encounter common operational challenges. Issues such as hydraulic system failures, engine overheating, or electrical malfunctions may arise during its use. Recognizing these potential problems is essential, as timely troubleshooting can prevent extensive downtimes and costly repairs. This is where the importance of having a comprehensive service repair manual becomes evident. Such a manual serves as a critical resource for operators and technicians alike. It equips them with detailed guidance on maintenance schedules, diagnostic procedures, and repair solutions that are vital for ensuring the harvester operates at its best.

Overall, the Tigercat LH855E Harvester stands out for its reliability, efficiency, and adaptability. Understanding its specifications, capabilities, and potential issues is crucial for any professional looking to maximize its function within the forestry sector.

Key Components and Maintenance Procedures

The Tigercat LH855E Harvester is a sophisticated piece of machinery designed for optimal performance in demanding forestry environments. At the core of its operation are several vital components, including the engine, hydraulics, and cutting systems. Each of these elements plays a critical role in the functionality of the harvester while also posing potential failure points if not properly maintained.

The engine is the heart of the LH855E, delivering the power necessary for various operations. It is essential to monitor the engine’s performance by keeping a close eye on oil levels and conducting regular diagnostic checks. This helps identify any irregularities that might indicate imminent issues, such as overheating or unusual noises, which could lead to costly repairs if left unaddressed.

Next, the hydraulic system is crucial for the seamless operation of attachments and movements such as boom elevation and arm control. Routine checks of hydraulic fluid levels and the condition of hoses and fittings are highly recommended. Insufficient hydraulic fluid or worn fittings can lead to pressure drops and a malfunctioning system, which may result in decreased efficiency or complete failure during operations.

Additionally, the cutting system, including the saw head and intertwining components, requires special attention. Ensuring that the cutting edges are sharp and the components are free from debris will significantly enhance performance and extend the lifespan of the equipment. Regular inspections for wear and tear should be performed to preemptively address any damage.

To maintain the Tigercat LH855E efficiently, following the service repair manual’s recommendations is necessary. This may involve routine checks, timely part replacements, and precise adjustments to ensure everything operates smoothly. Implementing these maintenance procedures can considerably reduce downtime and improve overall productivity.