Package Include

Bomag BW 211 D-4 , BW 213 D-4 , BW 214 D-4 and PD-4 Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1386

Publication Number

008 911 49 (06/2012)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 128 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bomag Road Roller Models of :

BW 211 D-4 / PD-4 [S/N 101 583 09 ….> S/N 101 583 10 ….>]

BW 213 D-4 / PD-4 [S/N 101 583 08 ….> S/N 101 583 13 ….>]

BW 214 D-4 [S/N 101 583 42 ….> S/N 101 584 15 ….>]

This Service Manual very clear, This is True Electronic pdf copy, not scanned version, contains high quality images and it is 100% printable version

Contents of this pdf manual

General

Introduction

Safety regulations

General repair instructions

Tightening torques

Technical data

Maintenance

General notes on maintenance

Fuels and lubricants

Table of fuels and lubricants

Running-in instructions

Caddy wiring diagrams

Understanding circuit diagrams

Circuit symbols in the circuit diagram

Identification of switch blocks in the Caddy wiring diagram

Designation of components in the wiring diagram

Terminal designations in wiring diagram

Plan wiring diagrams

Understanding wiring diagrams

Circuit symbols in the circuit diagram

Identification of switch blocks in the wiring diagram

Designation of components in the wiring diagram

Terminal designations in wiring diagram

Electrics

Battery ground and analog ground

Current and voltage

Pulse Width Modulation (PWM)

Resistance

Series / parallel connection

Ohm’s law

Electrical energy

Formula diagram

Metrology

Diodes, relays, fuses

Telemecanique switch

Plug connectors

Magnetic coil plug

Deutsch plug, series DT and DTM

Plugs and terminals in spring clamping technology

Acceleration transducer

Proximity switches

Level sensor in diesel tank (R03)

Differential pressure switch for hydraulic oil filter, B21

Oil pressure switch, B06

Air filter vacuum switch, B03

Sensor, water in fuel filter, B124

Charge control light (H08), operating hour meter (P00)

Float switch, coolant tank, B55

Coolant temperature switch, B30

Disassembling and assembling the coolant temperature switch

Boost fuel solenoid valve 125

Engine solenoid to shit down the engine, Y13

Electric throttle control

Fuel preheating, R79

Heating flange on engine, R19

Checking the heating flange control

Engine monitoring

Batteries

Battery service

Main battery fuse

Starting with jump wires

Generator 145

Replacing the voltage regulator

Electric starter 156

Disassembling and assembling the starter

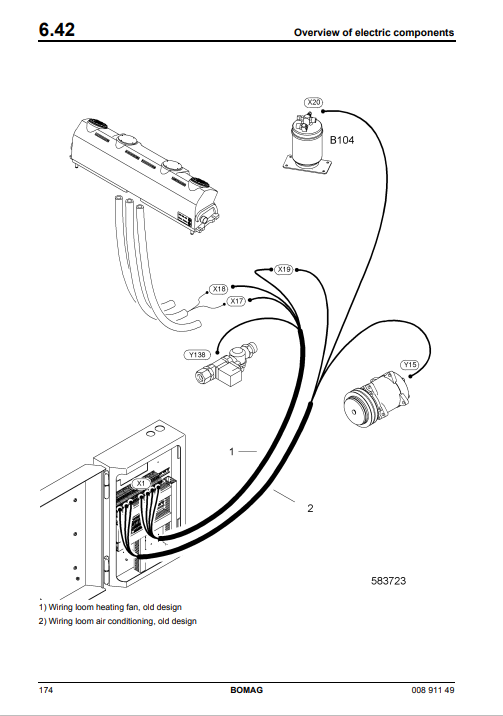

Overview of electric components

Operator’s stand, old design

Operator’s stand, new design

Cabin 182

Fuses, old design

Fuses, new design

Electronic control units

Checking the voltage supply for the control unit

Diagnostics concept

Electronic modules

BEM, BOMAG Evib-meter

Electrics module A68

Electric module K04

Electric module A72, old design

Electric module A108

Speedometer Module

Speedometer module

dust protection / 582 502 16 gasket

Assembling the dust protection

Hydraulics

Hydraulic circuit

Connection overview

Travel pump

Vibration pump 42R

Axial piston swash plate principle / pump

Troubleshooting axial piston pumps

Travel motor 51 C/D

Trouble shooting, variable displacement axial piston motor 316

Drum drive motor MSE 02 318

Vibration motor A10FM 45 321

Axial piston swash plate principle / motor 322

External gear pumps 324

Travel circuit 326

Stopping the machine, operating the parking brake 330

Towing in case of an engine failure 330

Adjust the parking brake 332

Vibration circuit 333

Steering circuit 338

Check the hydraulic oil level 344

Changing hydraulic oil and breather filter

Changing the hydraulic oil filter

Changing the bypass filter

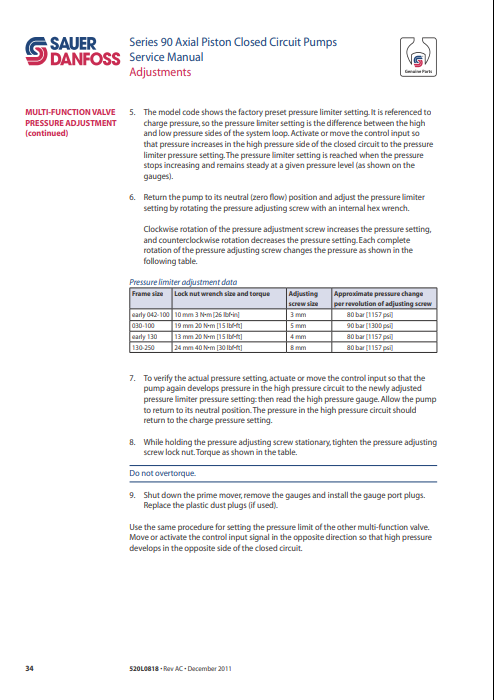

Tests and adjustments

Special tools, tests and adjustments

Checking the rotation speeds

Checking / adjusting the neutral positions of the travel pump

Pressure tests in the travel circuit

Checking / adjusting the vibrator shaft speeds

Pressure measurements in the vibration circuit

Check the leakage rate of the vibration motor

Pressure test in steering circuit

Flushing and bleeding

Special tools for flushing

Flushing – general

Flushing schematic travel circuit (distribution travel pump)

Flushing the travel circuit (travel pump distribution)

Flushing schematic travel circuit (distribution axle motor)

Flushing the travel circuit (axle motor distribution)

Flushing schematic for vibration drive

Flushing the vibration circuit

Bleeding the travel circuit

Bleeding the vibration circuit

Engine

Diesel engine

Fuel filter and check valve

Check, clean the water separator

Change the fuel pre-filter cartridge

Change the fuel filter cartridge

Changing engine oil and oil filter cartridges

Removing and installing the thermostat

Checking the thermostat in disassembled state

Change the coolant

Checking the anti-freeze concentration

Checking / replacing the ribbed V-belt

Combustion air filter service

Crankcase – disassembling and assembling the ventilation valve

Adjusting the valve clearance

Adjusting the control piston play

Checking the compression

Engine 429

Special tools, Deutz engine (TCD 2013 2V)

Air conditioning system

Physical basics

Refrigerant R134a

Compressor oil / refrigeration oil

Working principle of the air conditioning system

Monitoring devices

Description of components

Measuring the compressor oil level

Checking the magnetic clutch

Inspection and maintenance work

Checking, replacing the refrigerant compressor V-belt

Air conditioning service (old design)

Service the air conditioning

Drying and evacuation

Emptying in case of repair

Leak test

Filling instructions

Trouble shooting in refrigerant circuit, basic principles

Trouble shooting, refrigerant circuit diagram

Trouble shooting procedure

Steam table for R134a

Cabin assembly

Preparations

Cabin assembly

Final function tests and checks

Replacing the cab window panes

Assembly of window panes

Special tools, cabin windows

Auxiliary materials

Removing and installing the window pane

Drum

Special tools, drum, single drum rollers

Repair overview for drum

Removing and installing the drum

Repairing the drum

Dismantling, assembling the change-over weights

Changing the rubber buffers and adjusting the pretension

Oscillating articulated joint

Special tools, oscillating articulated joint (BW177 to BW 216)

Repair overview oscillating articulated joint

Removing and installing the oscillating articulated joint

Dismantling the oscillating articulated joint

Assembling the oscillating articulated joint

Suppliers documentation

Travel pump

Vibration pump

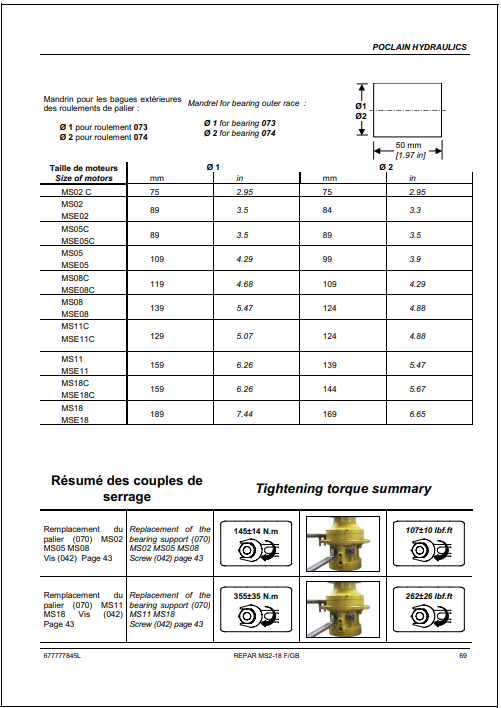

Drum drive

Vibration motor

Axle drive motor

Steering valve

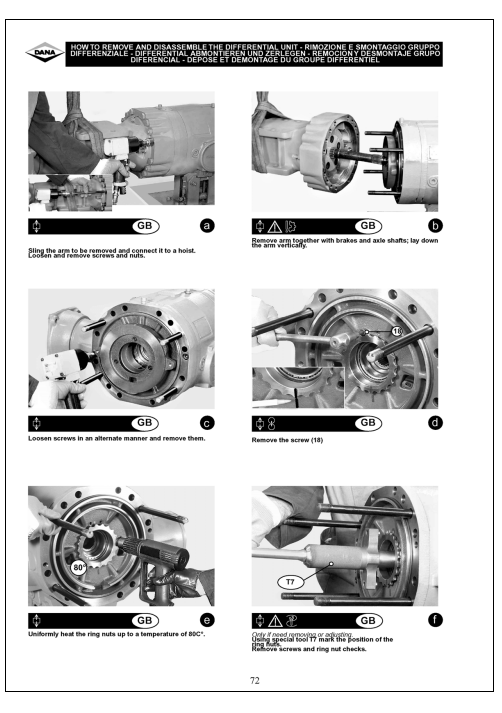

Axle

Circuit diagrams

Hydraulic diagrams

Wiring diagrams